- 产品描述

-

- Commodity name: New energy vehicle

The new energy vehicle industry involves the manufacture of a large number of precision parts, including motor parts, battery housings, transmission system parts, chassis parts, etc., High-precision, high-strength and high-reliability processing technology is usually required to ensure the performance and safety of the entire vehicle.

The new energy automobile industry involves the manufacture of a large number of precision parts, including motor parts, battery housings, transmission system parts, chassis parts and so on., Usually requires high-precision, high-strength and high-reliability processing technology to ensure the performance and safety of the vehicle.

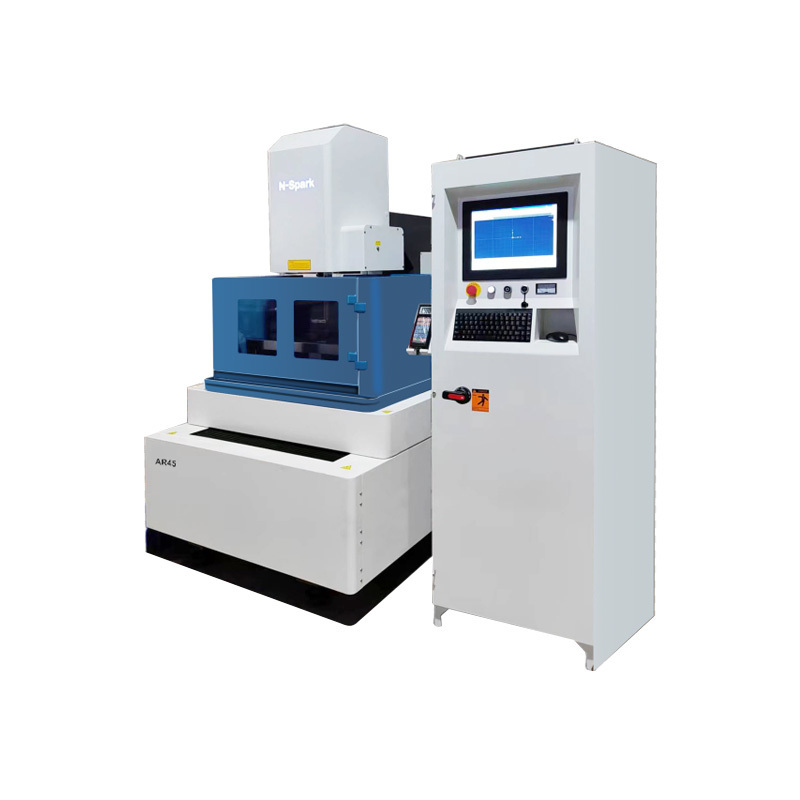

EDM forming machines are commonly used models for parts and components in the new energy automobile industry. They can efficiently process high-hardness materials, accurately manufacture complex-shaped parts, and meet the requirements of high-precision processing.These characteristics make electric spark forming machines play an important role in improving the quality and production efficiency of new energy auto parts.

Application case: A shipping company belongs to the world's top 500 and is a national first-class enterprise.Mainly engaged in the research, development, production and service of turbochargers, high-speed centrifugal compressor units, industrial steam turbines, and low-power gas turbines.The supercharger superalloy blades produced need to be perforated, and the processed holes are φ4.3mm; the depth is 8.0mm; the inner hole size error is ±0.01mm; the inner hole Ra is ≤1.0µm; the hole is symmetrical relative to the tenon and groove reference: X direction ≤0.05mm, Y direction ≤0.05mm.

Based on the customer's processing environment and process requirements, it is recommended that customers directly use a CNC spark machine to quickly process and penetrate, and then use the second half of the long electrode to flatten to process the hole wall finish to about 1.0µm.After testing and testing, the AF50 CNC spark machine penetrates and smoothes the light, which takes about 5-7 minutes.This scheme can place 20 blades on the workbench and process them in batches with a single electrode. This can reduce repeated manual operations, reduce processing processes, and reduce the error rate. At the same time, it saves labor costs and time.This plan was quickly recognized by customers, and the machine was quickly purchased and implemented.In the follow-up process, the customer gave a very high evaluation.

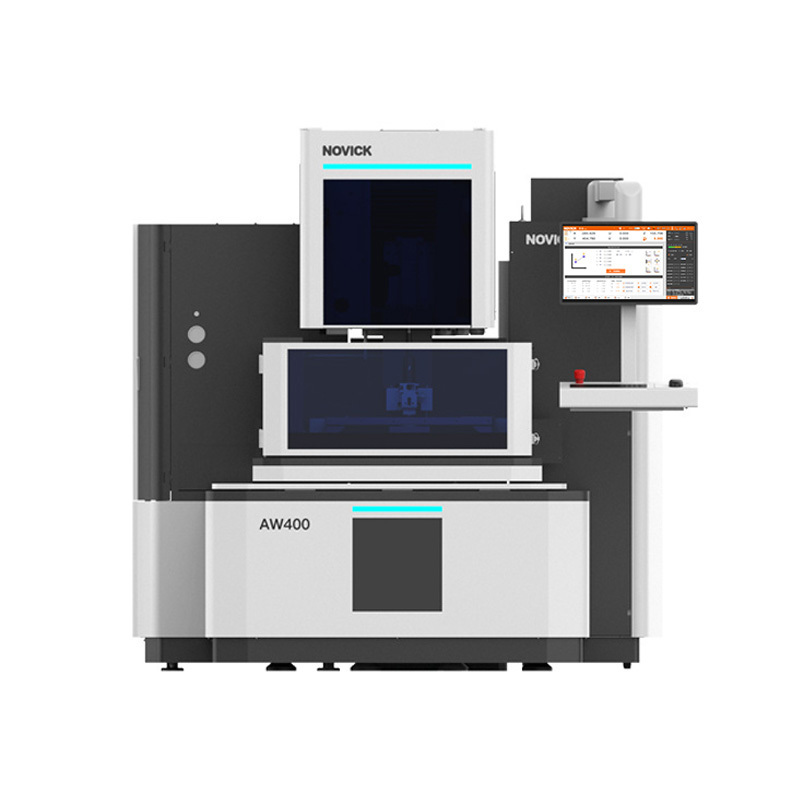

Wire cutting machines and forming machines play a key role in the manufacture of new energy auto parts.Among them, the wire cutting machine is suitable for the manufacture of key components such as motor parts and battery modules due to its high precision, complex shape processing and material diversity.The forming machine has the ability to form complex parts through efficient mass production, high-precision molding and complex parts, which meets the high demand for high-volume and high-quality processing in the new energy vehicle industry.The application of these equipment can protect the quality and performance of new energy automobile parts, and can adapt to the rapid development of the new energy automobile industry.

Related machine tool equipment

Room 501, 5th Floor, East Zone, Tower B, Building 2, Longsheng Plaza, No. A5 Rongchang East Street, Beijing Economic-Technological Development Area, Beijing, China

100176