- 产品描述

-

- Commodity name: Special Materials

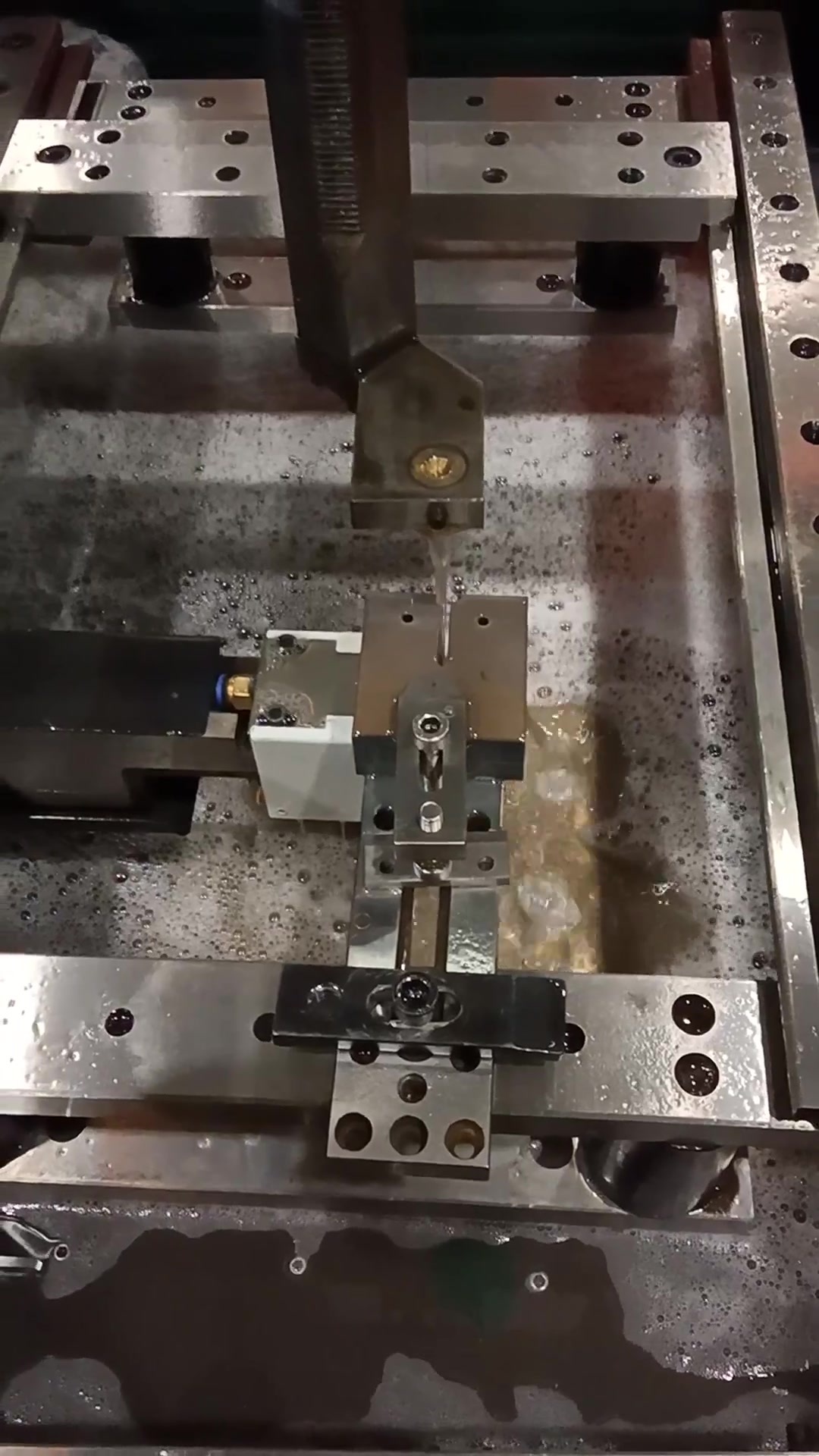

Electric discharge machining machine tools (EDM, Electrical Discharge Machining) have unique advantages in processing special materials.

Electric discharge machining machine tools (EDM, Electrical Discharge Machining) have unique advantages in processing special materials.Special materials usually include high hardness, high strength, high melting point or highly corrosive materials, such as titanium alloys, cemented carbide, silicon carbide, composite materials and superalloys.

Silicon carbide (SiC) is a kind of high hardness, high strength and high heat resistance material, which is widely used in electronics, machinery, aerospace and other fields.However, due to its special physical and chemical properties, there are many difficulties in the processing of silicon carbide.The following are the main difficulties and corresponding solutions of silicon carbide material processing:

Difficulties: The high hardness of silicon carbide is close to that of diamond, and it is highly brittle. Surface cracks, burrs and other defects occur during processing, which affect the surface quality and mechanical properties of the parts.It makes it difficult for traditional machining schemes to be carried out effectively.

Solution:

Option 1: Use CR's full range of tool processing machine tools to produce diamond tools (PCD) or cubic boron nitride (CBN) tools, which can effectively process high-hardness materials.

Option 2: Use AT50F model machine tools for precision grinding to achieve high precision and good surface quality.

Solution 3: Using the full range of CL, laser cutting and punching can effectively process silicon carbide parts with complex shapes and tiny characteristics.

Titanium alloy is widely used in aerospace, medical and automotive fields because of its excellent properties, but its processing is more difficult.Work hardening is prone to occur, making subsequent cutting more difficult, which will increase tool wear and increase costs.Titanium alloy is easy to bond with the tool during processing, resulting in titanium shavings attached to the surface of the tool, which affects the processing quality and tool life.

Solution:

Option 1: Optimize the cutting parameters according to the parameter library: choose a reasonable cutting speed, feed and cutting depth to reduce the work hardening effect. We have a powerful parameter library for titanium alloy single, multiple, precision, speed and other cutting processes.

Solution 2: Our company develops machine tools and has the latest special power-in method, which can solve the problem of easy bonding in processing titanium alloys.

Option 3: All series of machine tools have highly rigid machining beds, which can reduce vibration and deformation in titanium alloy machining.

Titanium alloy, silicon carbide and silicon wafers are all materials with special properties and are widely used in different fields.Electric discharge machining (EDM) and laser machining technologies have significant advantages in processing these materials with high hardness, high strength and high precision requirements.Through the use of these advanced processing technologies, complex shapes, high-precision and efficient material processing can be achieved to meet the needs of modern industry for high-performance parts.

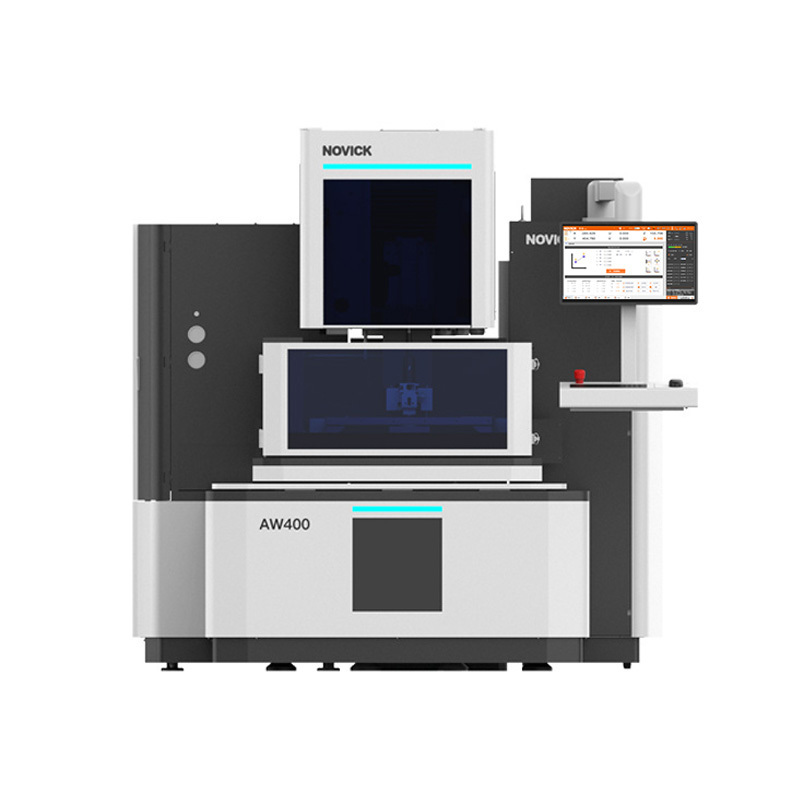

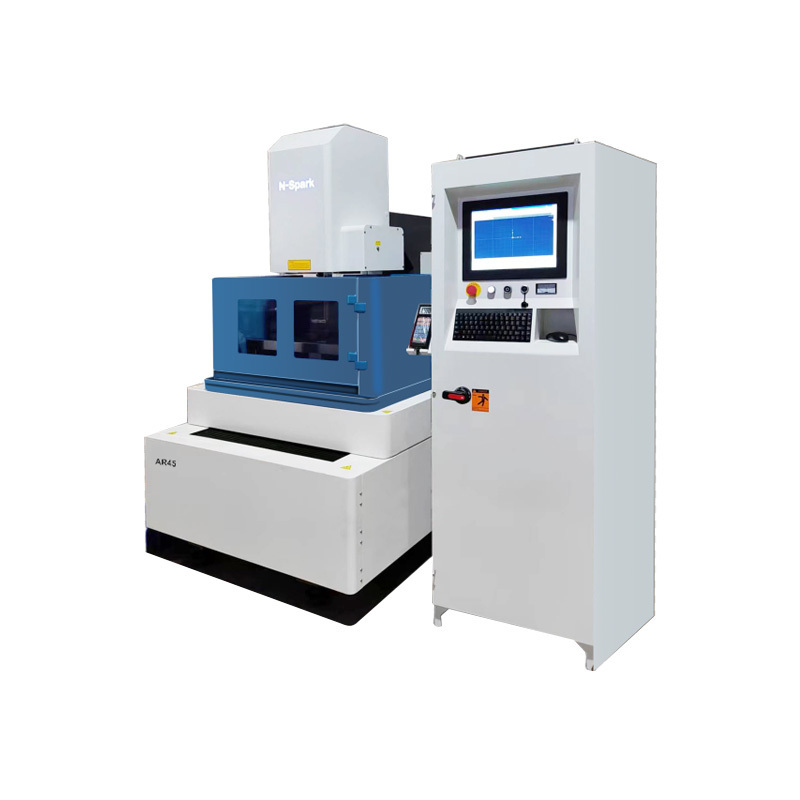

Related machine tool equipment

Room 501, 5th Floor, East Zone, Tower B, Building 2, Longsheng Plaza, No. A5 Rongchang East Street, Beijing Economic-Technological Development Area, Beijing, China

100176