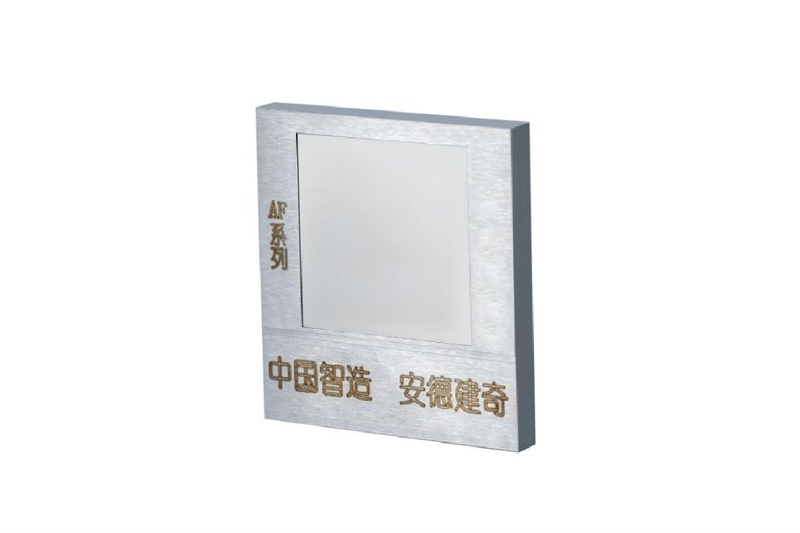

Precise CNC Die-Sinking EDM AF Series AF50

AF series precision CNC electric spark forming machine tools are newly launched upgraded products of our company.This series of machine tools adopts a new graphical operating system and has made major improvements in electrical and mechanical aspects, which have significantly improved the processing speed, electrode consumption and mirror processing effect of the machine tools.The machine tool is equipped with a remote control operation center and a 17-inch LCD touch display screen to make human-computer interaction more convenient.

This series of products is widely used in the mold industry, parts, aerospace, high-precision machining of special materials, and used to form automated production lines.

Keywords:

| Project | Unit | AF50 |

| Overall dimension | mm | 1750 × 1610 × 2400 |

| Weight of whole machine | kg | 2300 |

| How to open the door | Swing door/lift door | |

| Work table size | mm | 600 × 400 |

| Distance from Z-axis end face to work table | mm | 300~600 |

| Axis travel X/Y/Z | mm | 500 × 300 × 300 |

| Electrode and workpiece | ||

| Maximum electrode weight | kg | 70 |

| Maximum workpiece weight | kg | 1000 |

| Maximum workpiece size | mm | 800 × 500 × 300 |

| coordinate axis | ||

| X/Y/Z axis manual speed | m/min | 4 gears adjustable, up to 4 |

| X/Y/Z axis software pitch compensation | mm | 5 |

| X/Y/Z axis guide rail type | linear rolling guide | |

| Minimum angle clearance | μm | 20 |

| CNC | ||

| Control System | based on industrial computer system | |

| Operating System | Windows 10 | |

| Electronic disc | SSD greater than 32G | |

| Input mode | MDI、USB、LAN | |

| Display | 17 ″ LCD Touch Display | |

| control axis | XYZC four-axis, four-axis linkage (C-axis is optional) | |

| Interpolation type | Line/Arc | |

| Translating type | Automatic translation/servo translation | |

| Translatable mode | Round/Square/Vector/Polygon etc | |

| Remote Operation Center | ||

| Function keys | Axis selection and movement/movement speed and single step/pump/start/stop /pause/find edge/find hole center/move half way/return to zero/open chuck |

|

| Electric cabinet and processing | ||

| Standard power supply | 3 × 380V 50/60Hz 10KVA | |

| Maximum machining current | A | 50 (optional 100A) |

| Processing conditions Storage capacity | 1000 | |

| Maximum processing speed | mm³/min | 380±10%(50A)/550±10%(100A) |

| optimum surface roughness | μm | Ra≤ 0.1 (copper electrode, maximum electrode area 300mm ², workpiece material S136 mirror steel) |

| Optional Accessories | ||

| Extended processing current module | A | 100 |

| AC servo system | Panasonic | |

| Built-in C- axis | kg | Maximum electrode weight 15kg |

| X/Y/Z linear grating ruler | HEIDENHAIN resolution 0.25μm linear grating ruler (AC servo system shall be selected at the same time) |

|

| AEC Electrode Exchange Device | AF50:4 tool magazine; AF70:5 tool magazine | |

| Personalized customization | ||

| 1. Machine tool configuration; 2. Machine tool performance; 3. Special functions; 4. Personalized colors | ||

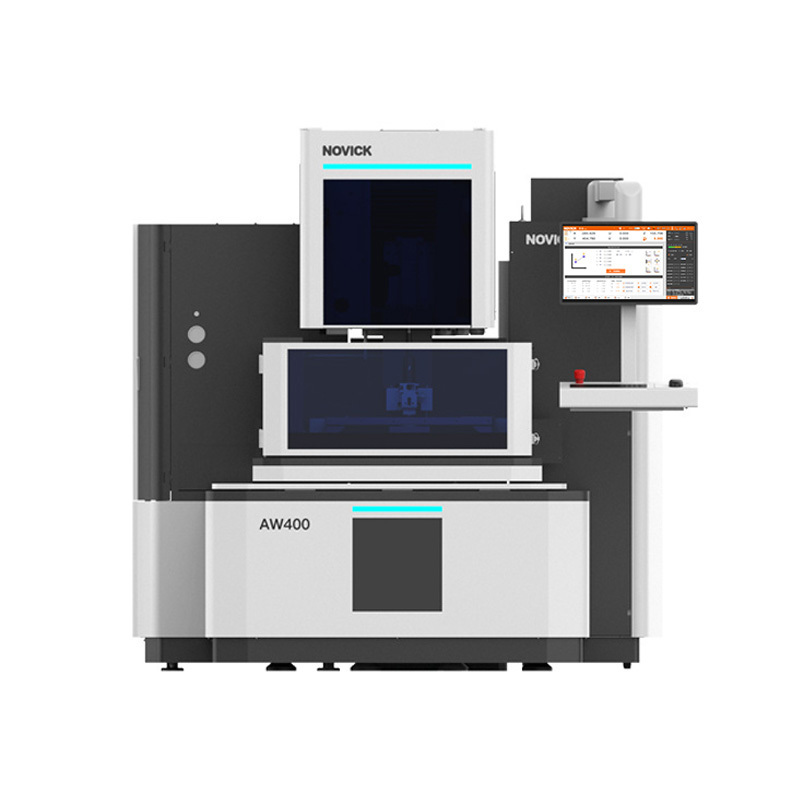

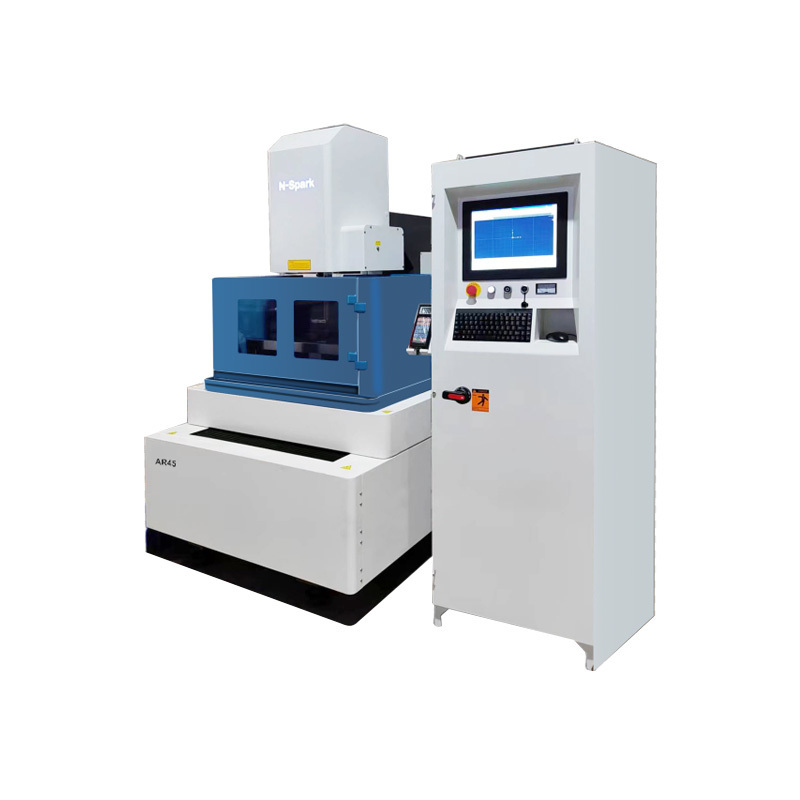

Related Products

Room 501, 5th Floor, East Zone, Tower B, Building 2, Longsheng Plaza, No. A5 Rongchang East Street, Beijing Economic-Technological Development Area, Beijing, China

100176