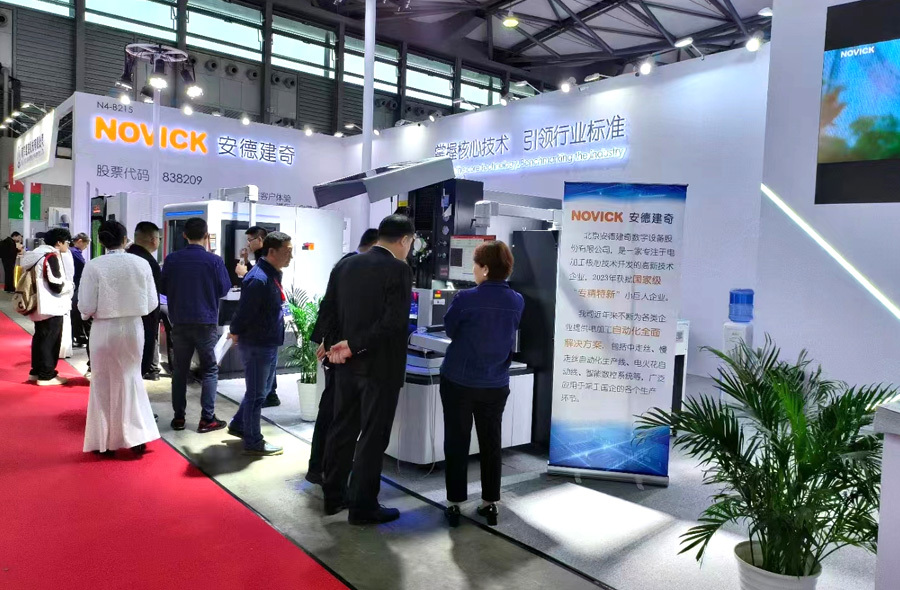

Our company participated in China CNC machine tool exhibition and won the CCMT2024 Chunyan Award

2024/04/17

Exhibit "MWE6 Pro-400 Automatic Wire Winding Precision EDM Medium Wire Cutting Machine" won the CCMT2024 Chunyan Award of China CNC Machine Tool Exhibition, and specially awarded the honorary certificate.

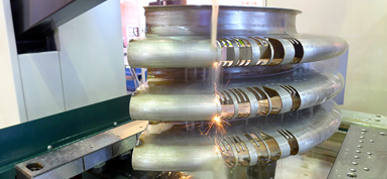

Correctly control the voltage and current of wire cutting

2024/01/25

Correctly control the voltage and current of wire cutting

How to correctly control the voltage and current of the wire cutting machine?Let's introduce it to you.

1.The voltage of the fast-moving wire and medium-moving wire cutting machine should be controlled between 70-90V during processing.

2.The processing current depends on the thickness of the workpiece to be processed to determine. Generally, if the thickness of the workpiece to be cut is below 70, the current can be controlled at 2-3A.

3.As for the current jumping to 4-5A all at once, it may be that your walking speed is too fast and the short circuit is caused.

EDM wire cutting is more troublesome, and it is necessary to adjust the pulse interval, pulse width, pulse... the value of the change is too large.

For the same type of wire cutting, the practices of manufacturers are different and the performance is different.The cutting efficiency is also different.

The no-load voltage is the voltage that turns on the high frequency but does not process the workpiece.As the thickness of the workpiece changes during processing, the no-load voltage will also change. During processing, the voltage will be lower than the no-load voltage, which is the so-called load.The thickness is different, and the load is different.

There is a voltage regulator inside the control box of the EDM wire cutting machine and an external rotary switch. The voltage can be adjusted by rotating the switch back and forth (it is strictly forbidden to adjust the voltage and change the pulse width, pulse spacing, and pulse parameters during cutting.There will be a risk of broken wires and destruction of circuit components).

How to deal with the “filigree” phenomenon of medium wire cutting machine tools

2024/01/25

How to deal with the “filigree” phenomenon of medium wire cutting machine tools

How to deal with the phenomenon of “filigree” encountered in the daily use of medium-distance wire cutting machine tools?The following Xiaobian will give you a brief introduction.

The cause of the phenomenon of “filigree” in medium-distance wire cutting machine tools:

Because it cannot be effectively deionized to form a continuous arc discharge, the resistance heat of the arc of the wire cutting machine tool precipitates a small amount of carbon to form fine carbon particles, and the molybdenum wire itself is also carbonized.One of the three is that the workpiece is thicker (long discharge gap), the dielectric coefficient of water is low (poor recovery insulation), and the pulse source has a DC weight (greater than 10mA) that delays arc extinguishing. These three are the basic conditions for the “filigree” scene.An “impurity” brought in (or inherent in the workpiece) in the discharge gap that affects the spark discharge is the cause of the “filigree” phenomenon.“Filigree” is the same as the arc-drawing burn of spark electric discharge machining. Once the arc-drawing burn in the gap is formed, the workpiece and the electrode will be burned out of the pit at the same time and form carbon fine particles. If the carbon fine particles are not cleaned, they cannot be processed.When the small carbon particles stick there, they will be burned by arcs, and the area will become larger and larger, and there will be no ability to remove them by themselves.If the workpiece and the electrode are displaced, each and the opposite side will cause new arc burns, one place will change to two places.The only way is for people to liquidate, and the line cutting can be done as a force.

Analysis and treatment of the ”filigree" scene of medium-moving wire cutting machine tools

After a period of cutting, dark spots will appear on the molybdenum wire for a period of time. The dark spots are usually a few to ten millimeters long, and the dark spots are usually a few to tens of centimeters apart.Dark spots are arc discharges that continue over a period of time, burn and carbonize.After thinning, brittleness and carbonization, it is easy to break.Dark spots form black spots on the silk tube, and sometimes they are arranged in a certain order to form patterns, so they are called "filigree”.

2024/01/25

A brief discussion on the maintenance and maintenance of machinery and equipment for cutting slow wire walking

How to maintain and maintain the machinery and equipment for cutting slow wire walking in daily use?The following Xiaobian will give you a brief introduction.

The slow wire cutting machine is a new type of machinery that gathers many high-tech technologies. It is classified as a category of machinery and equipment with high precision and density. The user must pass strict training before working so that he can enter the actual work.In order to ensure the safety of users, Ningbo slow wire manufacturer will briefly describe the main points that operators need to pay attention to for you.

It should be clear about the characteristics, functions, structure, etc. of the slow wire cutting machine, be familiar with the control process and follow the safety code of work; it should be processed within the range of models that can be cut off of the machine tool, and should not exceed the weight or exceed the stroke; it should be checked regularly whether the rotary button switch and the direction switch of the machine tool are intact and trustworthy, and can still be in operation in case of problems; the appropriate amount of lubricating oil or grease should be added to the lubrication place on time in accordance with the rules to ensure that the machine parts can operate normally, especially the guide wheels and bearings, which must be inspected, repaired and replaced on time.

Finally, I would like to remind everyone that in order to ensure the service life of the machine and the safety and reliability of the work, regular maintenance and maintenance must be carried out.

Room 501, 5th Floor, East Zone, Tower B, Building 2, Longsheng Plaza, No. A5 Rongchang East Street, Beijing Economic-Technological Development Area, Beijing, China

100176