- 产品描述

-

- Commodity name: Aerospace

Aerospace parts need to meet extremely high performance standards, including lightweight, high strength, high heat resistance and corrosion resistance.Manufacturing involves a variety of high-performance materials and complex processing technologies.

Aerospace parts need to meet extremely high performance standards, including lightweight, high strength, high heat resistance and corrosion resistance.Manufacturing involves a variety of high-performance materials and complex processing technologies.Through the reasonable selection of materials and processing methods, it is possible to ensure that the parts meet the stringent performance requirements and ensure the absolute safety of the aircraft.

Problems and solutions encountered during processing:

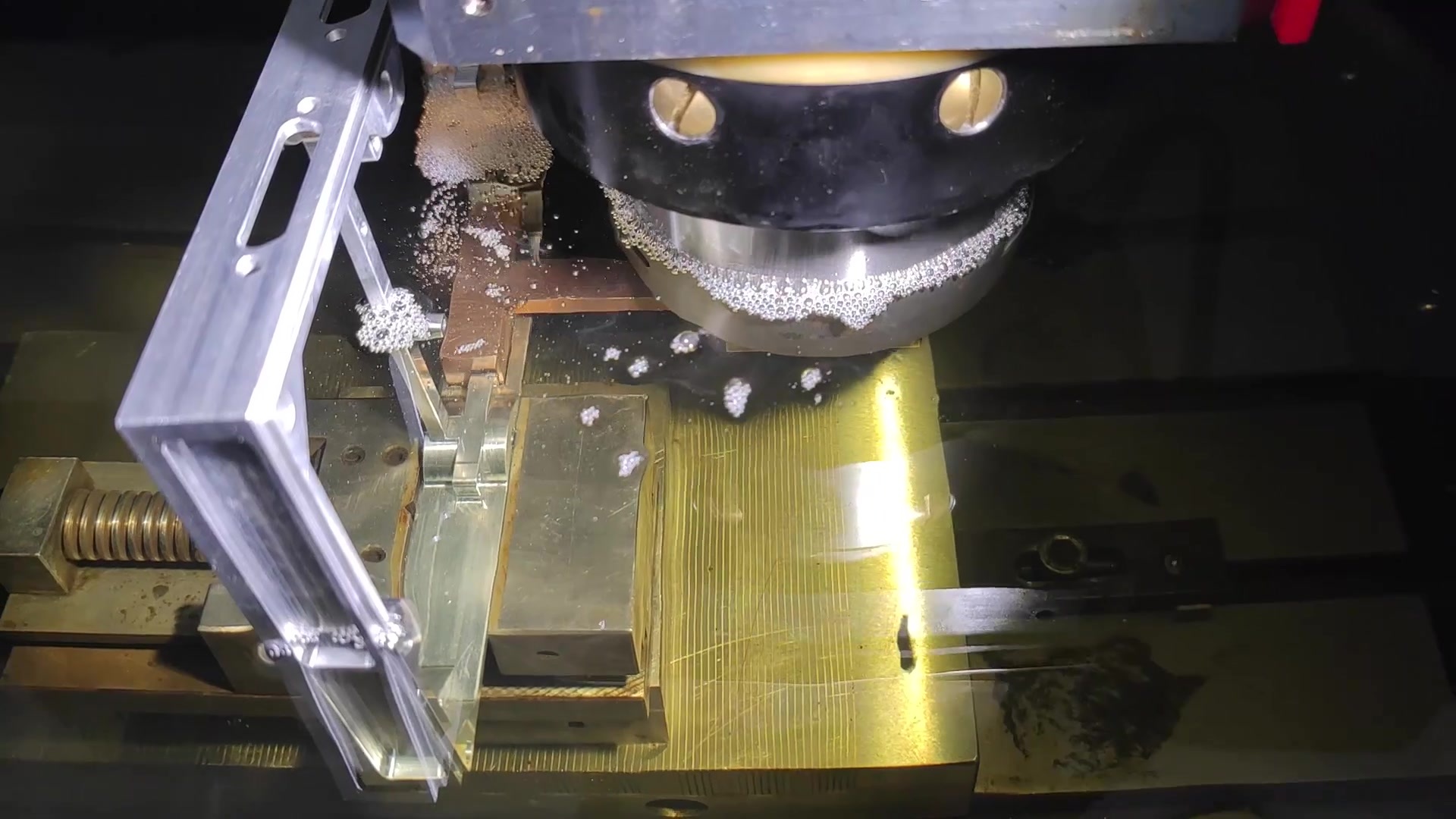

1.The inner cavity of the engine cooling honeycomb cannot be machined with milling cutters, which will cause the surface honeycomb to collapse.Using AF series spark machine electric discharge machining, no force is generated, and the honeycomb shape can be kept intact.

2.The tightly sealed groove between the blades has a groove width between 2-0.5 mm. Such a small groove width cannot be processed mechanically.It can be adjusted to use narrow-blade copper electrode electric discharge machining. AF series EDM machine tools are more suitable for processing special-shaped cavities that cannot be operated by mechanical knives.

Customer case:

An aero-engine manufacturing company mainly processes high-precision and complex-shaped aero-engine blades, combustion chambers, turbine components, and key components of various spacecraft.

Customer needs: The particularity of the aerospace field makes it extremely demanding on machining accuracy. The accuracy requirements are at the micron level, especially for the processing of key components, the accuracy needs to be within 0.005mm.While ensuring high precision, it is also necessary to ensure a stable processing state to meet the requirements of rapid delivery of large-scale production.

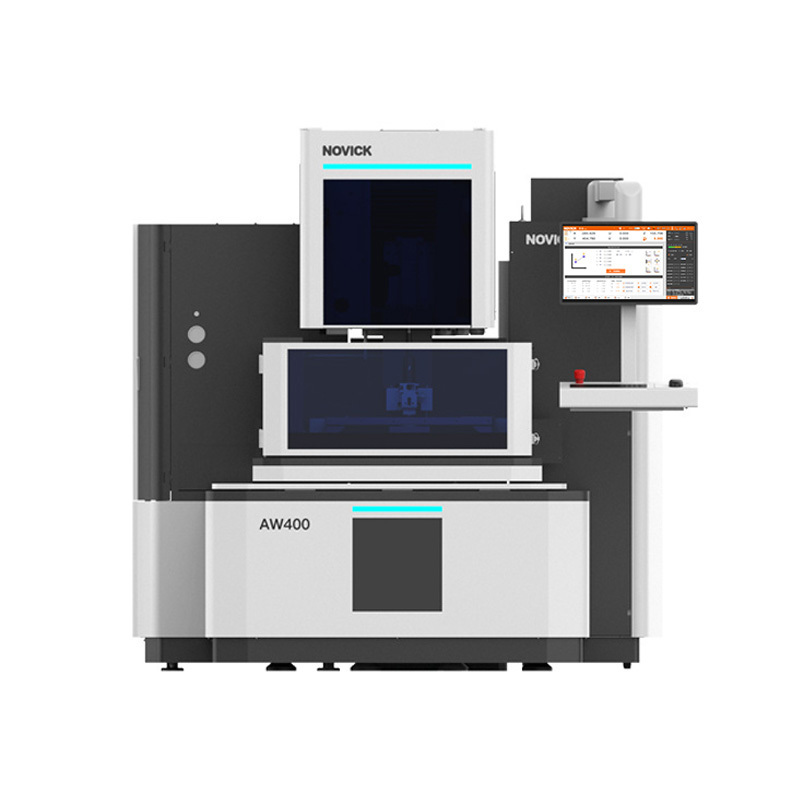

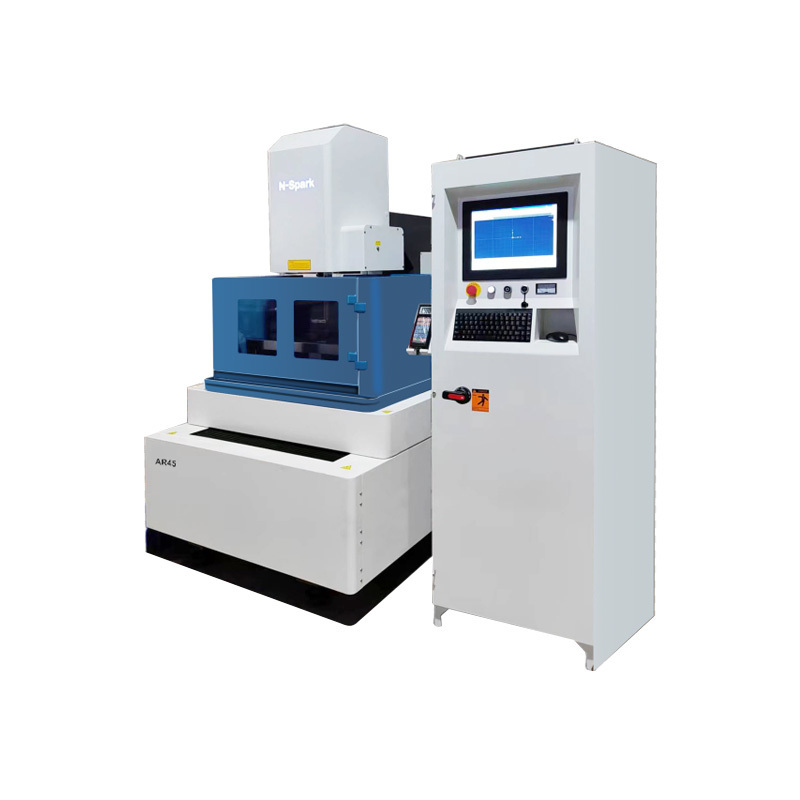

Provide a solution: The electric spark forming machine tool (EDM) removes metal through the electric spark discharge between the electrode and the workpiece, which can achieve extremely high machining accuracy and complex shape processing.EDM processing has no special requirements for material hardness, so it is particularly suitable for processing high-hardness and high-strength aerospace materials.At the same time, a complete set of processing solutions has been specially customized for customers in combination with other requirements.

Customer feedback: Customers have highly praised the performance of EDM machine tools in the field processing of high-precision and high-complexity parts.The high efficiency and high stability of the equipment have significantly improved production, shortened the production cycle, and met the customer's demand for mass production.The customer said: “The high-speed cutting capabilities of the equipment and the intelligent control system have greatly improved our production efficiency and can better respond to market demand.

This case shows the excellent application of our EDM in the aerospace industry and a typical example of winning the long-term trust of customers through high quality.

We will continue to work hard to provide better products and services to meet the growing needs of our customers.

Related machine tool equipment

Room 501, 5th Floor, East Zone, Tower B, Building 2, Longsheng Plaza, No. A5 Rongchang East Street, Beijing Economic-Technological Development Area, Beijing, China

100176