How to operate the spark machine

2021/11/12

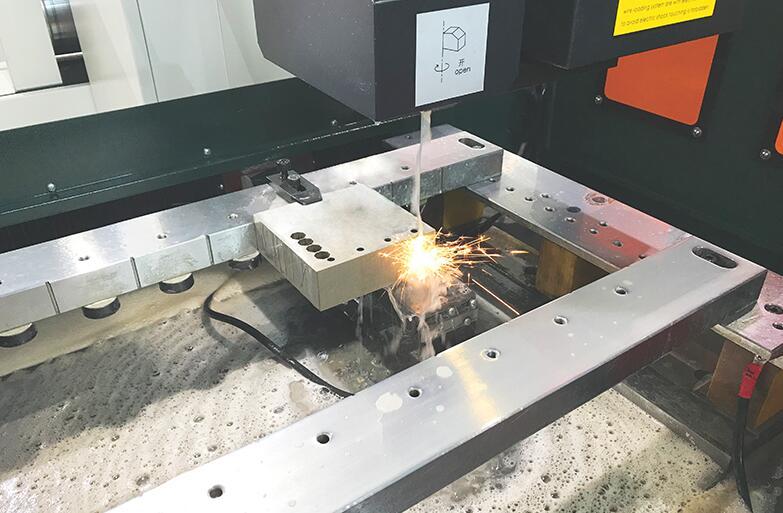

How to operate the spark machine

How to operate the spark machine, the following Xiaobian will summarize it for everyone.

1.The spark machine first checks that the main power switch is on.

2.Install the electrode and chuck, correct the vertical and parallel reference, place the workpiece on the magnetic workbench, and fix the magnetic absorption after correcting the parallel reference.

3.Use the electrode to find the discharge position of the workpiece X.Y coordinates, AT詷 to OA, PA20µS~45µS when searching for edges.

4.Polarity selection, (copper is the positive electrode, the workpiece is the negative electrode).

5.Current AT adjustment, the combination of discharge time PA, extensive discharge (electrode unilateral gap 0.12) ATS~45A, PA60s~120µs, the specific conditions depend on the size of the discharge electrode area, the discharge area is small, extensive discharge can be used 1.5a90µs (when less than 1mm2) to avoid excessive electrode loss; fine discharge (electrode unilateral gap 0.04), AT1.5~SA.PA20µS~60µs, when the discharge area of the fine discharge is large, first use AT1 .5PA60µS When the side wall is placed at about 0.1, switch to AT3A.PA30µS, leaving 0.030, then switch to AT1.5A.PA30µS and put it at 0.005, and finally repair 0.025 on one side (AT1.5A PA30µS).

6.Rest time PB, discharge gap voltage adjustment, PB3~4 when extensive, the gap voltage is adjusted to 3 or 4, PB is adjusted to 5 or 6 when fine repair, and the gap voltage is adjusted to 5 or 6.

7.Servo strength, rotation setting, when extensive, the servo is adjusted to 6 or 7, and the rotation time of the nose up and down is set to 5\4 or 4\4, respectively.When playing carefully, the servo is adjusted to 5, and the upper and lower rotation time of the nose is set to 5\2 or 6\3 respectively.

8.Turn on the liquid level control switch (the indicator light is flashing when it is turned on), and the sleep switch is turned on (the indicator light is on when it is turned on).

9.Manual servo feed, reach the position of the Z-axis datum, set the discharge depth, and when the depth is set, enter the data at the moment when the electrode is in full contact with the workpiece, and then perform Z-axis correction based on the difference.(Do not press the F1 switch down to set the depth).

10.The processing hydraulic motor is on, and the oil flushing position is adjusted.

11.The discharge switch is on.

12.Observe whether the V meter, A meter index, and servo stability indicator are stable.

13.Confirm whether the discharge position is correct.

14.The processed workpiece electrodes and related picture files are placed in the corresponding indicated positions.

The above is the operation method of the spark machine for your reference.